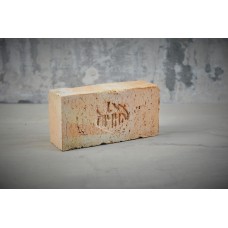

Refractory bricks, also known as fire bricks, are specially designed bricks that can withstand high temperatures without breaking down or deforming. They are used in a variety of industrial applications where high temperatures are required, such as in furnaces, kilns, and boilers.

Refractory bricks are made from high-quality materials that have high melting points, such as alumina, silica, and magnesia. The raw materials are mixed together and then formed into bricks using high-pressure machinery. The bricks are then fired in a kiln at extremely high temperatures to make them even stronger.

There are many different types of refractory bricks available, each with its own unique properties and uses. For example, high-alumina bricks are ideal for use in environments where high temperatures and abrasion are present, while silica bricks are ideal for use in environments where acid corrosion is a concern.

Refractory bricks are essential for a variety of industrial applications. For example, they are commonly used in the steel industry to line blast furnaces and other high-temperature equipment. They are also used in the cement industry to line rotary kilns and other high-temperature equipment used in the manufacturing of cement.

In addition to their high-temperature resistance, refractory bricks are also highly resistant to chemical attack, making them ideal for use in environments where chemical corrosion is a concern. They are also highly durable and can withstand heavy use over time, making them a cost-effective solution for many industrial applications.

However, while refractory bricks are highly durable and long-lasting, they do require proper maintenance to ensure their continued performance. Regular inspections and repairs are necessary to prevent damage from occurring and to ensure that the bricks continue to function properly.

In conclusion, refractory bricks are an essential component of many industrial applications, providing high-temperature resistance, chemical resistance, and durability. While they do require proper maintenance, they are a cost-effective solution for many industrial applications and are essential for the continued operation of many industries.